SERVICES

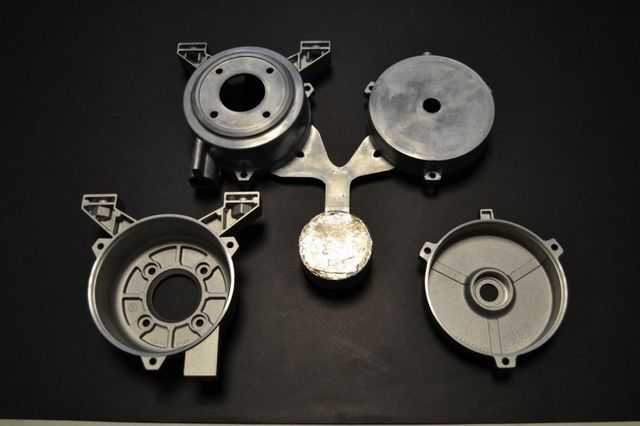

Die-Casting

We know that carrying out die-casting operations requires certain important certifications, without which it is impossible to certify the quality of such precision work; we must remember, in fact, that our products are not standalone items, but metal, aluminium, and alloy components to be inserted into engines, bodywork, electronic instruments, furnishings— and therefore must guarantee maximum reliability even before being functionally tested.

This is the reason that drives us every day to ensure maximum transparency, to work with dedication in compliance with all current regulations, and above all to make sure that our operations always respect the natural environment around us.

To ensure greater safety, each press has also been equipped with SPC software for statistical process control management, allowing us to monitor the parameters influencing the die-casting process at any moment, even remotely.

We are not the first, nor the only company to perform such die-casting work; but we strive to stand out from the crowd by offering a unique, complete service that allows us to act as a single point of contact for anyone in need of moulds and precision mechanical products to be adapted to the most diverse needs.

Assistance and Consulting

We are always

available to guide our clients in understanding the procedures we carry out at our state-of-the-art laboratories, so that everyone can have a comprehensive view of our activity and the commitment we put in every day in a sector so fundamental to every modern industrialised society.

Design and Production of

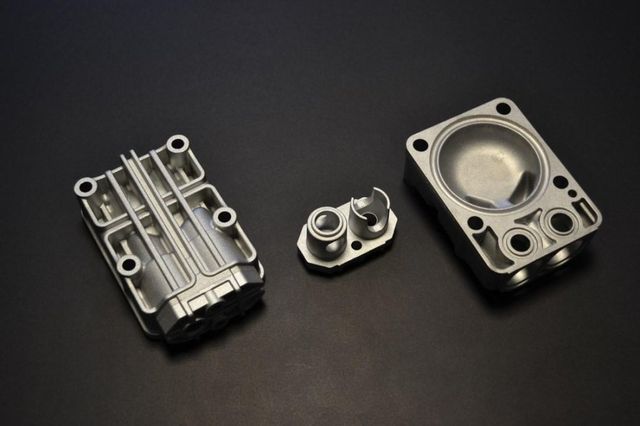

Die-Casting Moulds

Nuova Alupres is the company we have built to provide extra support to anyone with a mechanical industry who wishes to rely on specialists in metalworking, so they can benefit from top-quality products adapted to their projects.

Precisely the planning phase is one of those to which we pay the most attention, if only because it is this phase that defines the successful outcome of the final project. Our clients can count on the support of our staff, who, thanks to their experience, will be able to provide design assistance and guide users toward defining every detail and creating optimal solutions capable of fully satisfying their needs.

Also in this phase, we use innovative technology that allows us to create drawings with absolute precision and have a fairly concrete vision of what the product will be like once the production process is completed.

DESIGN

Nuova Alupres has equipped itself with a co-design studio, thanks to which today we can follow our clients with the utmost attention and make available every resource present in our facilities.

To ensure the respect and confidentiality of all sensitive data we come into contact with every day, we also have a protected data transmission system that guarantees the fast and secure transfer of information to safeguard privacy.

PLANNING

With the aim of providing a complete service, during the phases of designing and building moulds, Nuova Alupres offers various services such as processing all standards for mathematical models, filling and solidification simulation using Pro-CAST software, mould modeling using CAD-CAM systems, and manufacturing tooling through the use of the most modern CNC machines.

In this way, we are confident that our tools are employed to achieve mould suitability and casting quality, with an approach aimed at reducing risks and maximising benefits.

CNC MACHINING

Thanks to decades of experience in aluminium die casting, Nuova Alupres has developed a valid know-how in precision mechanical processing performed with automated transfer machines and today this places us as an international point of reference.

Having had the opportunity to support the needs of very different companies, but all united by a vision based on efficiency, our staff has also developed a recognised professionalism that allows us to always provide the most appropriate service for the particular situation of reference.

We never tire of reiterating our pleasure in following each user from the early stages of collaboration; we are fully aware of the fact that this is the best way to establish profitable and long-lasting relationships and we do everything so that all our customers can fully benefit from our innovative organisation.

Maximum customisation

We are also experts in designing equipment, to be adapted to the activities of both light and heavy industry technicians and thanks to our ability to fully understand the requests that are forwarded to us, we can achieve a very high level of customisation, so that our products represent one-of-a-kind models.

Precision

and timing

We are very keen to ensure that all the processes used in our laboratories are certified and of recognised quality; for this reason, the entire production process is controlled by a computer network, through which data relating to the progress of orders are collected and important information is collected that allows us to carry out elaborate quality controls.

Careful production planning carried out with sophisticated management software guarantees the customer constant efficiency and punctual supplies.