DIE-CASTING FOUNDRY

ALUMINIUM ALLOYS

IN REGGIO EMILIA

Innovation in metal processing

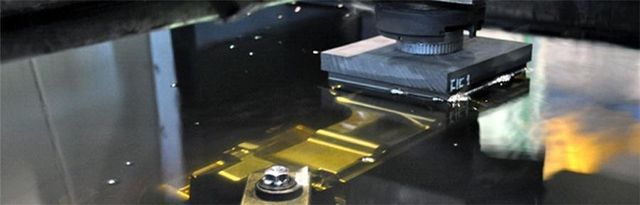

CNC Machining

- Aluminum

- Special Alloys

- Precision

- Punctuality

- Complex Projects

Mold Design and Creation

- Complete Design

- Design Assistance

- Optimal Solutions

- Effectiveness

- Innovative Technology

Fields

- Automotive Industry

- Furniture Industry

- Lighting

- Heating

- Home Appliances

Who We Are

Nuova Alupres is a company

specialised in the die-casting foundry sector, and for years has been committed to producing components in aluminium alloy. The process and materials used are suitable for the needs of the automotive industry, agriculture, electronic instruments, and generally for domestic and industrial furnishings.

Our production is carried out with great care and precision, following a certified and controlled process. The moulds are made with the best materials and with extremely high precision. This is to give the products unique and top-quality characteristics.

The company is equipped with cutting-edge tools and equipment in the industry, with low energy impact.

Strengths

Advanced Machinery

The foundry consists of 12 die-casting islands from 300 t to 1000 t, fully automated and capable of electronic process control; each machine is equipped with its own independent furnace, and this is the feature that allows us to carry out rapid material changes and meet the various needs of our customers.

QUALITY MOULDS

Nuova Alupres moulds are thermoregulated and subject to scheduled maintenance plans carried out internally. Every phase of the production cycle is rigorously monitored by company staff, and thanks to a sophisticated network-connected IT system, we are able to keep the entire production process under constant control.

ALUMINIUM ALLOYS

Our company specialises in die-casting any type of aluminium alloy.

In addition to the most commonly used alloys, such as EN AB-43400, EN AB-44300, EN AB-46000, EN AB-46100, EN AB-47100, we also use special alloys like Silafont 36, Unifont 94, ZA27C2, and other alloys upon customer request.

We are always available to guide our customers through the entire manufacturing process.

Innovation in Metalworking

Ours is a business founded on the passion and experience of those who still actively contribute today with their time and personal resources.

Technology for us represents something extremely fascinating, and this drives us every day to challenge ourselves, push beyond our limits, create highly competitive products, and provide our customers with top-quality materials to adapt to their own businesses.

We are all qualified technicians who deal daily with updates and specialist training courses; technological development is unstoppable, and we want to always stay up to date so we can offer optimal solutions in any circumstance and best meet the requests we receive from our loyal clients.

One of the great values of our work is the ability to always offer innovation, and thanks to our determination and the great professionalism with which we support each of our collaborators, over time we have succeeded in establishing important partnerships even with some of the most prominent foreign companies on the international market.

PRECISION

Our die-casting foundry is able to offer quality products from design to production. We guarantee maximum precision in the finishes; the entire production process is monitored through a network of sophisticated computers, allowing us to ensure constant efficiency and on-time deliveries for the customer.

Quality

We strongly believe that an efficient company does not base its strength solely on the quality of its products, even though this is still one of the main characteristics that sets it apart from the competition. Developing products in an artisanal way also means establishing a symbiotic relationship with customers— the starting point for any customised and precise work.

EFFICIENCY

In our company, moulds, castings, and all other die-casting foundry products can be modified at a later stage, applying transformations or coatings that enhance their physical resistance properties, even when such tools are subjected to high physical forces or extreme temperatures.